Old POL LPG cylinders are NOT compatible with new LCC27 LPG appliance connections.

New LPG appliance connections are ONLY compatible with new LPG cylinder valves.

Facts about LP Gas

When compressed, LP Gas becomes a liquid. When the liquid is released, the pressure drops, the liquid will turn to vapour which can be stored and used as a gas.

When it’s released from a cylinder and reverts to gas one volume of liquid expands to 270 times its volume. It’s about 1.5 times heavier than air which means that leaking LP Gas will fall to the ground. It has a distinct smell to assist you detect a leak.

Reporting gas incidents

All fuel gas accidents or incidents that occur in Western Australia must be reported to:

- the relevant gas supplier; and

- the Director of Energy Safety (Building and Energy).

This includes near misses, injuries or property damage relating to fuel gas (Natural Gas, LP Gas, CNG, LNG).

Building and Energy

Freecall 1800 678 198 (all hours, from anywhere in Western Australia)

During business hours, the calls are diverted to Building and Energy's Cannington Office (08) 6251 1900. Outside of business hours, the calls are diverted to an after-hours answering service. This freecall number only applies to incidents and accidents that occur within Western Australia.

Local gas suppliers

Supagas Tel: 1800 093 336

Origin Energy Tel: 1800 808 526

Elgas Tel: 1800 819 783

In the event of fire, an LP Gas cylinder should be removed from the heat source. If this is not possible, keep the cylinder cool by spraying water on to it. However, if flames are threatening to engulf the cylinder, the area should be evacuated and emergency services notified immediately.

Emergency services

Police Dial 000

Fire Brigade Dial 000

Safe use of LP Gas cylinders

Following these tips can’t ensure your LP Gas cylinder will be used and stored safely.

- Cylinders must never be laid down. Always keep cylinders upright even during transportation, when they must be well secured.

- Ensure that gas appliances are only operated in adequately ventilated spaces.

- Never tamper with a cylinder or valve. If excess force is needed to open or close the cylinder valve, or if the valve is damaged in any way, notify the supplier.

- Ensure that cylinders are always kept away from sources of ignition or heat.

- When any leakage from the cylinder valve is detected, move the cylinder to a safe location at least 20 metres from any sources of ignition and when empty, return to the supplier with a tag attached explaining the fault.

- Only use appliances designed for LP Gas which will be marked with a badge or label.

- Ensure that all gas fitting work is performed by a person authorised to do so.

- Dry chemical fire extinguishers are suitable for LP Gas fires.

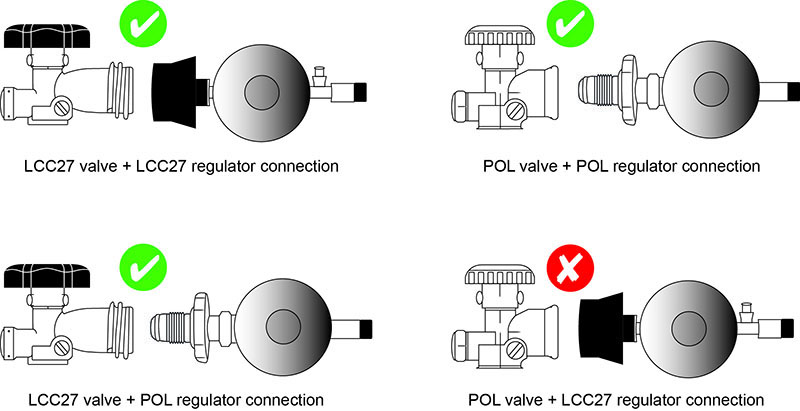

LPG cylinder valve transition – Type 21 POL to LCC27

In 2021, the LCC27 connection was phased in from the current Type 21 POL design to minimize the risk of fires and accidental gas leakage from LPG cylinders.

While the old Type 21 POL appliance connection is cross-compatible and can be used with both the old and the new cylinders, the new appliance connections are only compatible with new cylinder valves.

The LCC27 connection works by shutting off the gas flow where the hose is not connected to the LPG cylinder or in a fire situation.

The new LPG cylinder connection has additional safety advantages over the old Type 21 connection that are expected to significantly reduce the number of cylinder connection fires and injuries.

The new cylinder valve incorporates a check valve that will only enable gas to flow when a gas tight connection is made, reducing the risk of high pressure gas escaping if the cylinder valve is opened during transportation or disconnected during use.

The new connection features a large diameter right-handed thread that can be operated without the use of tools.

The connection also incorporates a thermal shutoff that allows the internal check valve to close and remove gas supply if the connection is exposed to a fire.

Banned LP Gas cylinder adaptors

From 1 April 2021, LCC27 valves replaced POL valves to improve safety and reduce the risk of barbecue fires and accidental gas leakage from LP Gas cylinders. The existing POL valves are being phased out over a 10-year period.

Following a Perth homeowner receiving severe burns while using a barbecue a Building and Energy investigation found that while the gas appliance was fitted with the new LCC27 appliance connector, an adaptor was used which caused the safety valve to not operate.

What is an LP Gas cylinder adaptor?

It is a fitting that is used to convert an old POL cylinder valve outlet to the new LCC27, allowing the older POL cylinders to be used with the new LCC27 appliance connector.

The valve connection adaptors override the improved safety feature of the LCC27 that provides a positive isolation of gas supply preventing the gas to flow unless a gastight seal or connection is formed between the valve and barbecue hose connector.

These safety hazards contribute to the risk of explosion and injury when operating LP gas appliances, such as a gas-powered barbecue.

The adapter ban

As a result the Director of Energy Safety has issued a prohibition order prohibits the sale, hire and use of LP gas cylinder adaptors that convert old Type 21 (POL) to new Type 27 in Western Australia. The Type 27 is commonly called the Leisure Cylinder Connection Type 27 (LCC27) or Quick Connect Coupling (QCC).

What to do:

- Use a gas cylinder with the new LCC27 cylinder valve with a new LCC27 gas appliance connector; and

- Do not use an adaptor to connect your old POL gas cylinder with the new LCC27 gas appliance connector.

- Old appliances with a POL connection hose can be used with a gas cylinder with the newer LCC27 valve.

Bushfire prone areas

Domestic 45kg LP Gas cylinders do not pose a significant additional hazard during bushfires, provided they are correctly installed, stored and maintained.

LP Gas cylinders should be:

- outside of buildings, nominally at ground level;

- not under a building or stairway;

- on a firm, level and non-combustible base;

- secured to a solid structure;

- clear of combustible materials; and

- positioned so the safety valves point away from adjacent structures and cylinders.

Ask your licensed gasfitter about the safest ways to store and use your LP Gas cylinders correctly. All gasfitting work, including relocating the regulator or piping, must be performed by a licensed gasfitter.

The safety valve

LP Gas cylinders have a safety valve on top which is protected by a plastic cap. In high temperatures, the safety valve automatically releases gas to protect the cylinder. When enough gas has been released the safety valve automatically closes.

The safety valve operates independently of the hand valve and will continue to work if the cylinder is turned off.

If the temperature rises enough for the safety valve to operate, you will hear a loud hissing noise, like a jet engine. There may also be a fireball. This is normal however people should remain at a safe distance from the cylinders.

Actions during a bushfire

If a bushfire is approaching, and provided it is safe to do so, follow the steps below:

- Turn off all cylinders with the hand valve (located on top, turn in a clockwise direction).

- Leave all cylinders installed, secured in an upright position.

- Ensure the area around the cylinders is free of combustible materials.

- Do NOT cover the cylinders with wet material to keep cool as it may dry out and become combustible.

- If the cylinders are exposed to heat, and if safe to do so, hose them down with water to reduce the pressure.

Maintenance

Any damage to the cylinder, such a dents and gouges, will affect the cylinder’s integrity. Inspect your cylinders regularly and contact your supplier if you are concerned.

If a cylinder is exposed to a fire, the steel may be damaged and the cylinder will need to be removed from service. Again, contact your supplier if you are concerned.

Installing a support structure

45kg LP Gas cylinders should be restrained from falling over to ensure the safety valve operates as intended. When considering how to restrain cylinders, the construction of your house needs to be taken into account.

Cylinder restraints for LP Gas cylinders are different for:

- single brick or framed walled buildings; and

- double brick buildings.

Double brick walls will generally remain standing after a fire, so a restraint system bolted to the wall is acceptable. A suggested design for securing LP Gas cylinders against double brick or concrete walls is shown on the download: LP Gas cylinder safety in bushfire prone areas.

If there is a likelihood that the wall will fall over during a bushfire, then securing the cylinder against the wall will not be sufficient and, an additional structure is recommended.

Single brick and framed walls are likely to fall over during a fire, so securing the cylinders to a separate support structure is recommended.

A suggested design for support is available in the publication: LP Gas cylinder safety in bushfire prone areas.

Links

- Supagas (Kleenheat)

- Origin Energy

- Elgas